Case study / IT Alpha

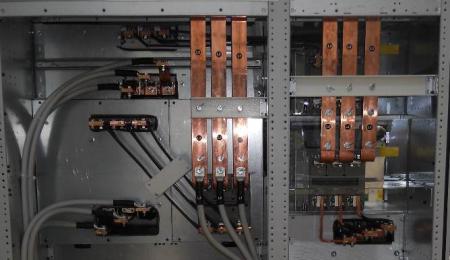

Design and production of automation switchboards for process management and supervision

In productive plants, the relative control and management of the same are of utmost importance in order to guarantee best performance and prevent plant stoppage due to breakdown that requires predictive actions of short time interventions.

Process automation and latest generation PLC control and management of the same coupled with SCADA systems that guarantee process monitoring, reporting, logging and implementation in real time from anywhere in the world with an internet connection, today represents the necessary elements for good performance of a productive plant. With the extra value of IT know-how, even the most demanding customer is guaranteed high plant performance.

Thanks to Partners and specifically trained technicians in brands such as SIEMENS-ABB-SCHNEIDER ELECTRIC – OMRON and GENERAL ELECTRIC, IT today represents a trusted and reliable supplier for its customers.

Starting from the study and process evaluation, IT is able to plan and define the plant control and supervision system by means of a specific connection and programming of the INPUT and OUTPUT of the PLC and by a specific SCADA Systems configuration and Operator Touch or Electromechanical Panels remote controlled in the Control Rooms.